- Offers the excellent fluidity to water-based flexo ink, suppresses ink rebound to the roller, and achieves improved transfer performance.

- Covers a wide range of materials, from porous substrates such as paper and wood to non-porous substrates like plastic film.

- Significantly improves the transfer performance of flexo ink, providing a vibrant finish.

- Compatible with both roll and doctor-blade methods.

- Exhibits effectiveness even at concentrations of 1% or less.

- Unique transfer enhancement properties enable pigment reduction of 5-15%.

- Imparts excellent flow properties even with challenging pigments like carbon black.

- Not alter the viscosity of the ink.

|

- Excellent performance on porous substrates such as paper, leather, and wood.

- Excellent storage stability, and remains highly stable even after addition.

- Effective at any stage of addition.

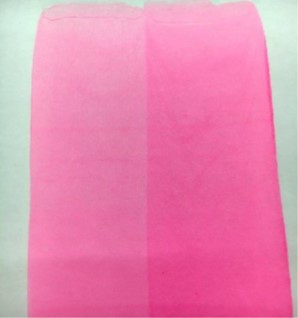

【Photo】Substrate: Paper, Left 0%, Right 1.0% added

- Can also be used as an anti-misting agent during the transfer process.

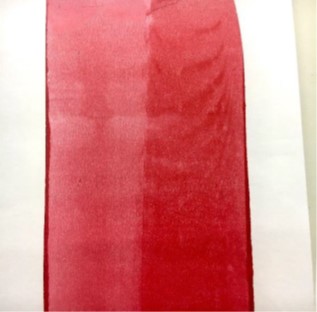

- Effective on non-porous substrates such as film and high-density paper.

- Complies with FDA regulations (175.300/175.170/176.180).

- Effective at low addition levels (during letdown). Recommended dosage: 0.5-1.0%

【Photo】Substrate: metalized paper, Left 0%, Right 1.0% added

- Contributes to a 10-15% reduction in pigment due to improved transfer performance.

- Effective on non-porous substrates such as film and high-density paper.

- Versatile compatibility.

- Not requiring other additives or fillers.

【Photo】Substrate: Paper, Left 0%, Right 1.0% added